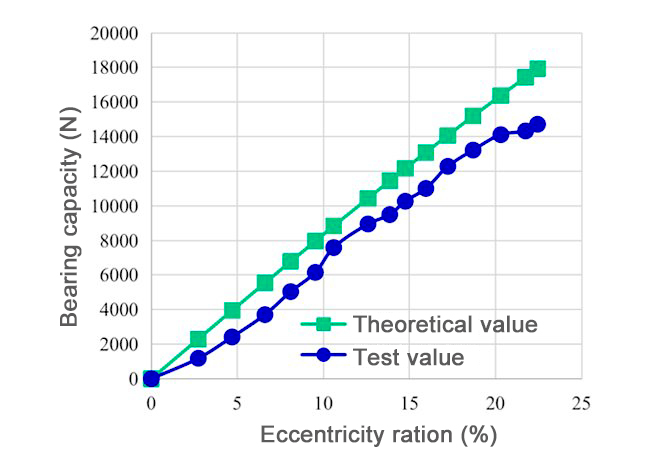

Zhefu Nuclear Power independently developed the lubrication property analysis program for gap throttling and capillary throttling hydrodynamic and hydrostatic journal bearings, and built a performance test bench for vertical slide bearings, which can test the capacity, stiffness, and damping factor of hydrodynamic and hydrostatic journal bearings. Based on the above, sodium-lubricated and lead-bismuth-lubricated hydrodynamic and hydrostatic journal bearings have been developed and put into practical use, and their performance has become industry-leading.

Zhefu Nuclear Power has developed the welding process for cobalt- and nickel-based high-temperature resistant cemented carbide powder, and complete welding for curved surfaces such as planes, and inner and outer cylindrical surfaces. The maximum welding area is more than 2㎡, the welding thickness is up to 7mm, the surface hardness is more than 45HRC, the hardness uniformity is less than 3HRC, and no visible cracks on the surface are detected through PT.

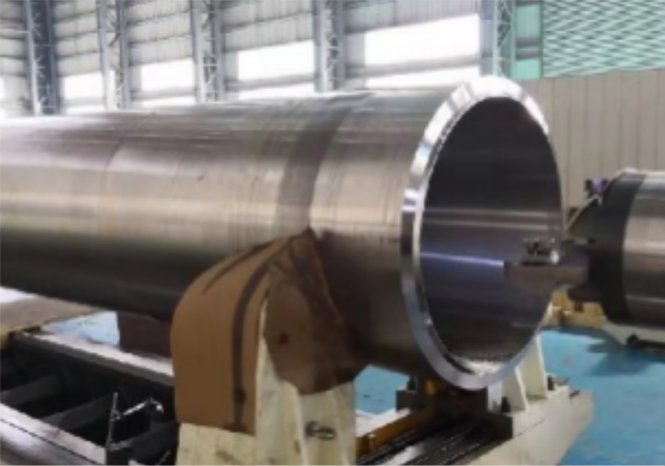

Zhefu Nuclear Power has enabled deformation control in welding and aligning of ultra-long, large-diameter, multi-section shafts. Based on this capability, it has successfully completed manufacturing two-section hollow shafts with a diameter of 800mm and a length of 12m, and controlled its dynamic balance accuracy to G1.6.

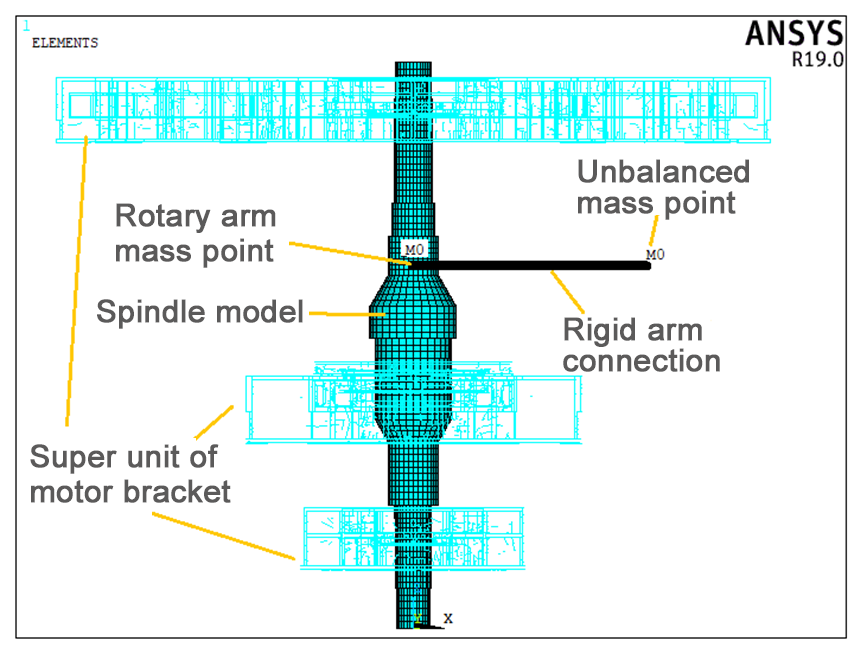

Zhefu Nuclear Power has the ability to equate the radial bearing into a two-vector spring unit and damping unit coupling, establish a characteristic curve between the position of the shaft center and the characteristics of the bearing, and dynamically simulate the movement trajectory of the shaft center. Zhefu Nuclear Power has the ability to equate the radial bearing into a two-vector spring unit and damping unit coupling, establish a characteristic curve between the position of the shaft center and the characteristics of the bearing, and dynamically simulate the movement trajectory of the shaft center.